Lower Embodied Carbon Concrete

At Ozinga, we value providing a product that benefits the earth and its natural resources. Our approach to designing our concrete mixes and transporting it to jobsites supports that value. We want to enhance the communities in which we live, work and play through our sustainable concrete that includes an optimized mix of recycled cementitious and non-cementitious materials used in combination with our specially formulated admixtures.

CARBONSENSE®

We developed a product line of ready mix concrete, recycled aggregates, and performance cementitious products to reduce concretes carbon impact on construction and infrastructure. CarbonSense® products and solutions have been specially designed and tested to help you reduce carbon emissions and reach net-zero targets. What’s more, all of our concrete produced in our service area is all developed, tested, and validated in our CCRL/ASTM-certified research & development lab using ConcreteAI™. This innovative technology is a proprietary machine learning program that allows us to shorten the time to market by predicting strengths and performance of a mix design without numerous iterations of mortar and concrete trials.

WHAT IS EMBODIED CARBON?

What exactly is embodied carbon? This refers to the emissions of greenhouse gasses emitted from the development, transporting, and installation of building materials. Accumulatively speaking, embodied carbon is the carbon footprint that a building has during construction before becoming fully operational. Upon completion, the CO2 emissions of a building’s lighting, heat and energy usage make up a structure’s operational carbon.

| READY MIX CONCRETE | AGGREGATES | CEMENT |

|---|---|---|

CARBONSENSE®  |

RECYCLED CONCRETE               |

PERFORMANCE CEMENT               |

CARBONSENSE® PLUS                             |

PERFORMANCE SCMS                             |

|

CARBONSENSE® ULTIMATE                                           |

CARBONSENSE® CEMENT                                           |

CARBONSENSE® CONCRETE PRODUCT LINE

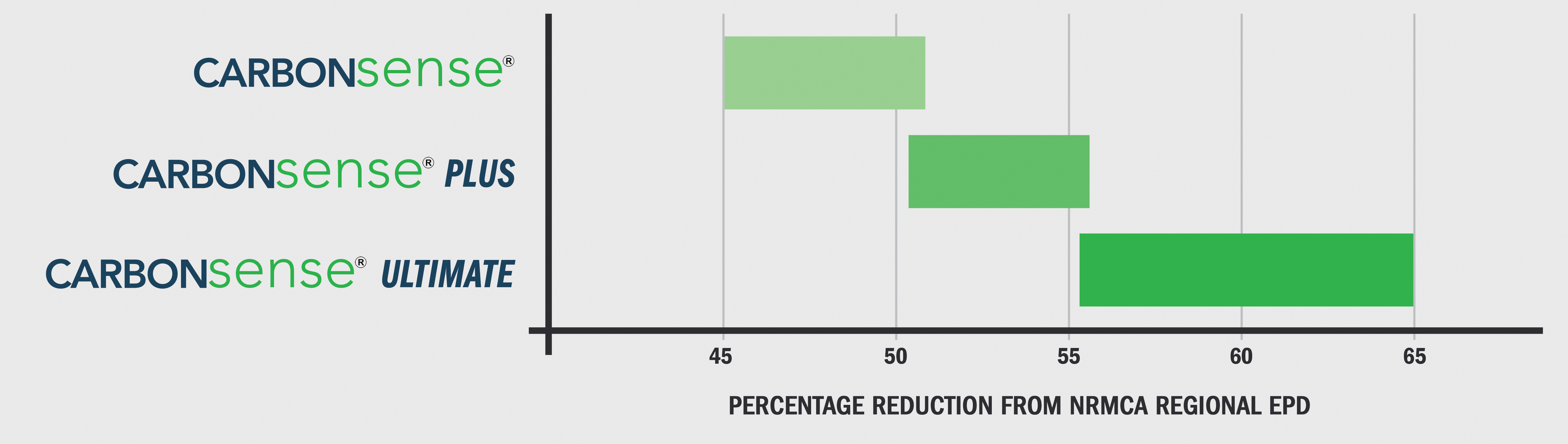

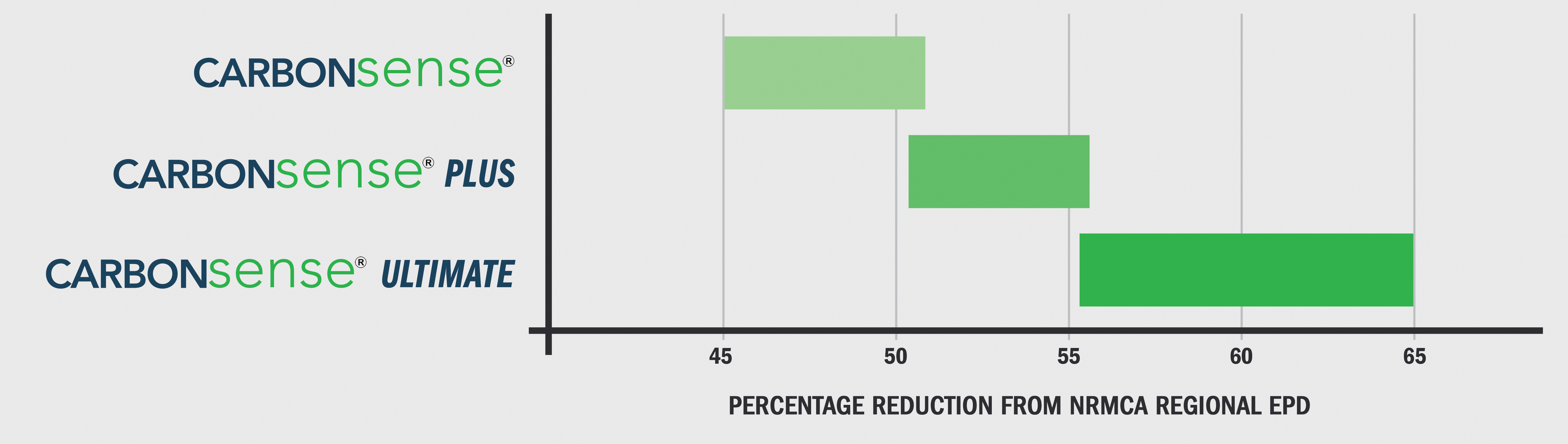

EPDs

We provide plant and mix-specific Environmental Product Declarations (EPDs) in accordance with strict international standards certified by ASTM. These EPDs are third-party verified documents that quantify the environmental information for the lifecycle of a product to allow for comparisons of other products with the same function. By evaluating these EPDs, designers and builders can determine the long-term environmental impact of products.

It’s vitally important to discuss project specs and net-zero targets as early in the process as possible, especially with material suppliers. Discuss your sustainability goals with us to learn more about how you can build greener with less embodied carbon. We're able to provide EPD documentation for any product at any of our many locations. To see a list of all our locations, visit our locations page.

Rieth Riley Solution

Requiring years of intricate planning, one of the most intimidating challenges Rieth-Riley faced was finding a concrete mix-design that would not only advance the University of Notre Dame’s sustainability efforts, but also be durable enough to withstand the power of the river. In the construction industry, there tends to be a misconception that sustainable mixes

Continue Reading